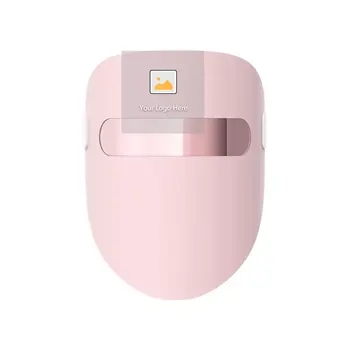

SKB-1818P Beauty care wireless colorful light therapy led facial therapy mask

A combination of red/yellow/orange light will rejuvenate and brighten the skin, reproduce a perfect skin rich in collagen.

It contains protective sunglasses, not dazzling during the treatment. Gentle light, safe and relax.

Smart auto timer, each mode 10 minutes for precise skin care.

Suitable for all skin types, including sensitive skin.

Short press the power button to switch skin care mode easily.

The product is lightweight, simple in structure, and ready to use when powered on.

It contains protective sunglasses, not dazzling during the treatment. Gentle light, safe and relax.

Smart auto timer, each mode 10 minutes for precise skin care.

Suitable for all skin types, including sensitive skin.

Short press the power button to switch skin care mode easily.

The product is lightweight, simple in structure, and ready to use when powered on.